- Logistics

- Visibility

12 Real-Time Transportation Visibility Platforms of 2025

Real-time transportation visibility platforms (RTTVPs) are transforming the logistics landscape by providing businesses effective tools to track and monitor their shipments in real time. As supply chains grow increasingly complex, the need for immediate access to accurate data has become critical. These shipment visibility platform use advanced technologies such as GPS, sensors and artificial intelligence to deliver live updates on the status and location of goods. This enables businesses to respond quickly to disruptions and optimize their operations. With enhanced visibility, businesses can improve customer satisfaction, reduce operational costs and make informed decisions that drive efficiency throughout the supply chain.

What is a Real-Time Transportation Visibility Platform?

Real-time transportation visibility platforms are advanced digital tools designed to provide comprehensive, live tracking of shipments throughout the supply chain. Utilizing technologies such as GPS, RFID and IoT, these platforms enable stakeholders like shippers, carriers, and logistics providers to access real time information regarding the location, status and estimated time of arrival of the goods in transit. This visibility is crucial for managing potential disruptions caused by factors such as traffic, weather conditions or customs delays. By offering features like predictive analytics and instant notifications about delays, RTTVPs enhance decision-making capabilities, improve customer satisfaction through transparency and contribute to overall supply chain efficiency by reducing costs and minimizing delays.

Key Factors to Consider While Choosing a Real-Time Transportation Visibility Software

When selecting a real-time transportation visibility software, it's important to consider key factors to ensure it aligns with your organization's needs. Below are the essential factors to keep in mind:

Data accuracy and reliability: The main feature of any real time transportation visibility platform is its ability to provide accurate and reliable data. This includes real time updates on shipment locations, estimated arrival times and alerts for delays. The platform should employ advanced technologies to ensure that the data is not only precise but also actionable, allowing businesses to make informed decisions quickly.

Integration capabilities: A real time transportation visibility platform must seamlessly integrate with existing systems. This integration facilitates a smooth flow of information across various departments and stakeholders, enhancing the overall operational efficiency. Choose a platform that supports easy integration to minimize disruption during implementation and maximize long-term benefits.

Scalability: As businesses grow, their logistics needs evolve. It is crucial to select a visibility platform that can scale with your operations. The software should accommodate increasing shipment volumes and additional functionalities without needing a complete system revamp. This scalability keeps the investment worthwhile as your business expands.

User experience: A user-friendly interface is vital for ensuring that all team members can easily navigate the platform and access necessary information without extensive training. The logistics visibility software should provide easy-to-use dashboards, customizable alerts and straightforward reporting features to enhance user engagement and productivity.

Cost-effectiveness: While investing in a logistics visibility platform can provide significant ROI through improved efficiency and reduced operational costs, it is essential to evaluate the cost against the features offered. Consider both upfront costs and ongoing subscription fees when assessing overall affordability.

Customer support and training: Effective customer support is important to help address any issues that may arise during implementation or regular use of the software. Ensure that the provider offers training resources, responsive customer service, and ongoing support. A strong support system can help mitigate challenges and enhance user satisfaction over time.

Regulatory compliance: In industries where compliance with shipping regulations is critical, it becomes vital to choose software that helps ensure adherence to these standards. The software should provide auditable records of shipment conditions and timelines for easier compliance with local and international regulations. This feature not only protects your business but also enhances trust with customers and partners.

12 Top Real-Time Visibility Platforms

In today's fast-paced logistics landscape, real-time visibility platforms have become essential for optimizing supply chain operations and enhancing customer satisfaction. Here is a list of the top twelve real time visibility platforms:

1. FarEye:

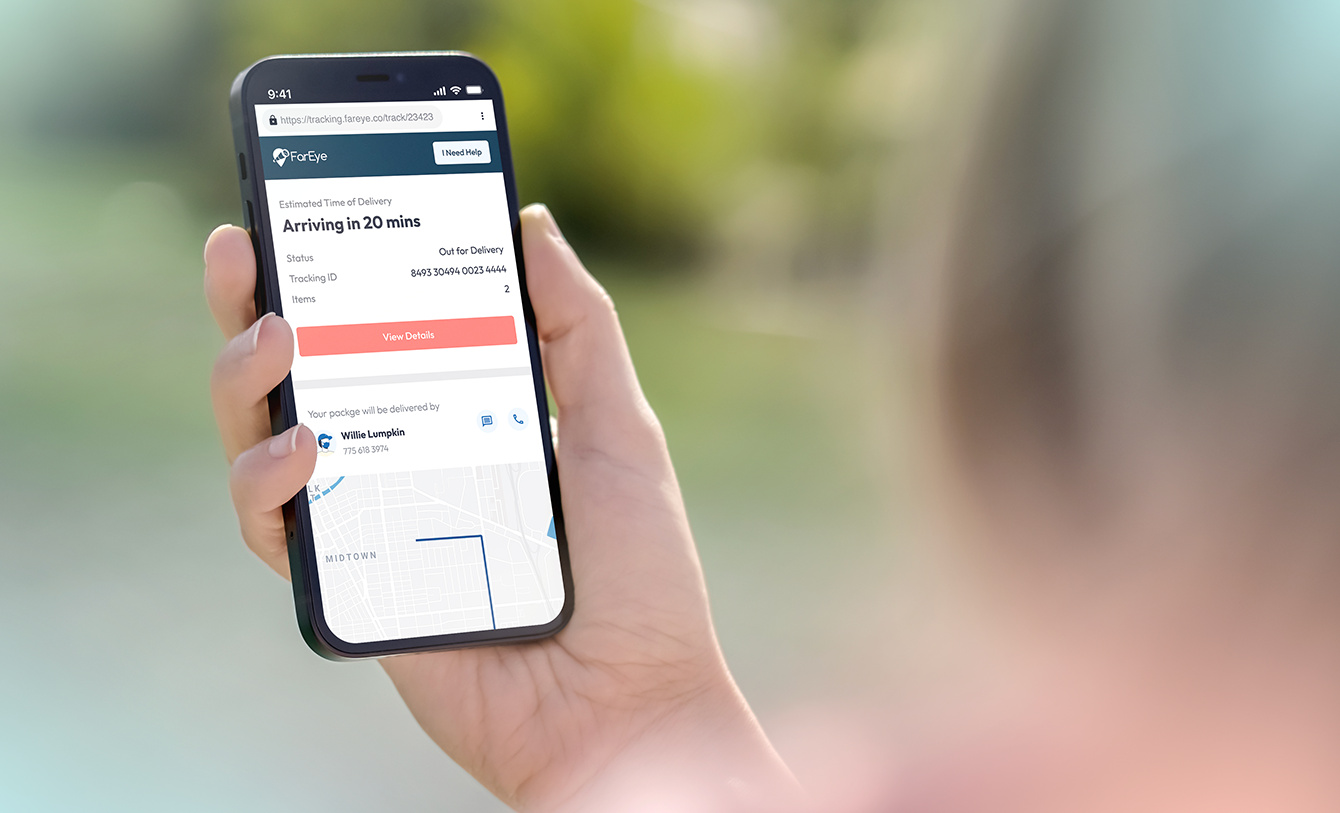

FarEye is a leading real-time visibility platform transforming logistics and delivery operations through its comprehensive suite of features. The platform excels in real-time tracking, enabling businesses to monitor shipments and vehicles at every stage of the delivery process. This transparency is crucial for ensuring timely execution and enhancing customer satisfaction. FarEye's advanced route optimization capabilities help create efficient delivery paths based on real-time traffic and weather conditions, reducing delays and operational costs.

One of FarEye's key features is its proof of delivery management, which digitizes the documentation process, streamlining billing and settlement while minimizing discrepancies. The platform integrates with over 250 last mile carriers, allowing for precise package tracking and accurate estimated time of delivery calculations. FarEye’s machine-learning algorithms enhance ETA accuracy, helping businesses set realistic expectations for their customers.

FarEye’s user-friendly interface and low-code/no-code setup facilitate quick onboarding of carriers. This adaptability makes it suitable for businesses of all sizes and complexities. With a strong focus on sustainability, FarEye not only simplifies last mile logistics but also helps businesses achieve their operational and sustainability goals while enhancing customer satisfaction. Its comprehensive features make it the best choice for businesses seeking to optimize their supply chain visibility and delivery performance.

2. e2open:

e2open is a cloud-based platform designed to provide comprehensive supply chain visibility through real time data integration and collaborative planning. The platform enables businesses to align operations among different stakeholders, promoting a more unified approach to supply chain management. With features like demand sensing, inventory optimization and supply chain analytics, e2open empowers organizations to respond swiftly to market changes and customer demands.

A key advantage of e2open is its networked supply chain model which connects multiple partners in the supply chain ecosystem. This connectivity fosters collaboration, enabling businesses to share critical information seamlessly and make informed decisions based on real time data. The platform also supports advanced analytics and machine learning capabilities that help predict potential disruptions, allowing businesses to proactively manage risks.

Additionally, e2open enables the users to track their carbon footprint across the supply chain. Its intuitive dashboard provides actionable insights that help businesses optimize logistics processes while minimizing environmental impact. Overall, e2open is a logistics visibility platform beneficial for businesses looking for a collaborative approach to supply chain management.

3. GoComet:

GoComet is a digital freight management platform that focuses on providing real time visibility into shipping operations while automating logistics processes. Its user-friendly interface allows businesses to monitor shipments across various transport modes such as air, sea or land, ensuring transparency throughout the shipping lifecycle. GoComet’s shipment tracking capabilities enable the users to receive updates on shipment status in real time, which enhances communication with customers and stakeholders.

One of GoComet's standout features is its cost management tools which help the users analyze freight costs. The platform integrates with multiple carriers and provides instant quotes based on real time data, allowing users to make informed decisions quickly regarding their shipping options. This feature not only saves time but also helps organizations optimize their logistics budgets.

GoComet promotes collaboration among stakeholders by enabling easy communication between shippers and logistics providers through its integrated messaging system. Its emphasis on automation reduces manual tasks, increasing efficiency in logistics operations while minimizing errors. For businesses looking for an effective shipment visibility platform that combines visibility with cost-effectiveness, GoComet offers a compelling option.

4. SAP Integrated Business Planning:

SAP Integrated Business Planning (IBP) enhances supply chain visibility through advanced analytics and planning capabilities. By integrating various functions such as demand planning, inventory optimization, sales forecasting and financial planning into a single platform, SAP IBP enables businesses to align their operations more effectively with market demands.

The platform's collaborative features allow teams from different functions such as sales, marketing and operations to work together seamlessly on supply chain initiatives. This collaboration helps businesses respond more quickly to changes in demand or supply disruptions.

SAP IBP also incorporates machine learning algorithms that enhance predictive analytics capabilities. This functionality helps businesses anticipate disruptions before they occur by analyzing historical data and current market conditions. Additionally, SAP IBP supports scenario planning, enabling businesses to evaluate different strategies based on varying market conditions or unexpected events.

With its robust capabilities for managing complex supply chains efficiently while providing real-time insights into performance metrics, SAP IBP stands out as a good choice for large enterprises seeking comprehensive planning solutions and enhanced visibility.

5. Overhaul:

Overhaul specializes in providing end-to-end visibility in supply chains with a focus on risk management and compliance monitoring. Its platform combines real-time tracking with advanced analytics to ensure the safety of shipments throughout their journey. Overhaul's emphasis on security is evident in its ability to monitor temperature sensitive goods and detect potential theft or tampering which are crucial for industries such as pharmaceuticals or food.

One of Overhaul's main offerings is its incident management system, which allows the users to respond quickly to disruptions by providing actionable insights based on real-time data. This capability enhances decision making during critical situations by equipping the stakeholders with the necessary information to take immediate action.

Overhaul’s user-friendly interface facilitates easy access to vital information about shipments while promoting compliance with regulatory requirements throughout the shipping journey. The real time visibility platform also provides tools for performance benchmarking against industry standards, helping businesses identify areas for improvement.

For businesses prioritizing security and visibility in their logistics operations, Overhaul presents a potent solution that not only enhances operational efficiency but also safeguards valuable assets throughout the supply chain journey.

6. Fourkites:

Fourkites is a real-time visibility platform that focuses on providing comprehensive tracking solutions across the supply chain landscape. Its robust features include predictive analytics that help businesses anticipate delays and optimize routes, ensuring timely deliveries while minimizing costs associated with inefficiencies.

The platform offers extensive visibility into both inbound and outbound shipments, allowing the users to monitor cargo at every stage of transit from origin to destination. This level of transparency is crucial for maintaining customer satisfaction by providing accurate updates regarding shipment status.

Fourkites also emphasizes collaboration by providing tools for communication between shippers and carriers through its integrated messaging system. This feature helps build stronger relationships among stakeholders while ensuring everyone remains informed about any changes or delays in real time.

Another notable aspect of Fourkites is its ability to generate alerts regarding shipment status changes, ensuring stakeholders are promptly notified when issues arise so they can take corrective action. Fourkites is a good choice for organizations seeking an intuitive platform that combines visibility with proactive analytics capabilities.

7. Shippeo:

Shippeo provides comprehensive visibility using advanced technology to deliver real-time insights into shipment status across multiple transport modes such as road, rail, sea or air. The shipment visibility platform integrates data from various systems to provide users with a unified view of their logistics operations.

Shippeo’s focus on predictive analytics enables businesses to foresee potential disruptions before they occur by analyzing historical data alongside current market trends. This proactive approach helps businesses optimize logistics strategies effectively while minimizing risks associated with unexpected events.

The platform excels in offering detailed reporting capabilities that allow users to analyze performance metrics over time. It provides valuable insights into areas such as carrier performance or delivery times. Shippeo also prioritizes collaboration by facilitating communication between shippers and carriers through its user-friendly interface, enhancing overall efficiency within the supply chain ecosystem.

Shippeo also supports sustainability initiatives by providing insights into carbon emissions associated with transportation activities, allowing organizations to track their environmental impact. For businesses aiming to enhance operational efficiency while maintaining environmental responsibility within their logistics operations, Shippeo offers valuable tools designed specifically for modern logistics challenges.

8. Shipsy:

Shipsy uses artificial intelligence and automation to enhance supply chain visibility and operational efficiency. Its AI-powered platform addresses critical challenges in logistics particularly in the last mile. Shipsy's advanced algorithms streamline processes by automating freight procurement, enabling shippers to request quotes from multiple freight forwarders with just one click. This not only simplifies the negotiation process but also ensures competitive pricing through dynamic bidding.

One of Shipsy’s standout features is its real-time tracking capability which provides customers with automated updates and predictive insights regarding shipment statuses. This feature significantly boosts customer satisfaction. The platform also allows users to personalize delivery slots and payment methods, catering to individual preferences and enhancing the overall customer experience.

Shipsy employs machine learning to minimize routing errors and optimize shipment processing. The integration of AI enables proactive incident management allowing businesses to quickly reorganize their supply chains in response to predicted delays. With its focus on automation, data-driven insights and real-time visibility, Shipsy empowers businesses to navigate the complexities of modern logistics effectively.

9. Tive:

Tive is a real time transportation visibility platform that specializes in tracking shipments using advanced IoT devices and sensors. This technology is particularly crucial for industries that handle sensitive goods such as pharmaceuticals, food and electronics, where maintaining specific environmental conditions like temperature and humidity is vital.

One of Tive's key features is its ability to provide real time data on shipment conditions, allowing businesses to monitor critical parameters during transit. This capability helps businesses respond quickly to any issues such as temperature fluctuations or unexpected delays. By equipping users with actionable insights, Tive empowers them to take corrective actions before issues escalate, minimizing potential losses.

The platform's intuitive interface makes it easy for users to access vital information regarding their shipments. This accessibility enhances communication among stakeholders, ensuring that everyone involved—from logistics managers to end customers—is kept informed about shipment status and any changes that may occur.

Additionally, Tive supports proactive risk management by generating alerts for potential issues, enabling businesses to maintain high service levels and customer satisfaction. Its robust analytics capabilities allow businesses to analyze historical data trends and optimize future shipping strategies.

For businesses seeking precise monitoring capabilities and comprehensive visibility solutions tailored to their unique needs, Tive offers an effective option that enhances operational efficiency while safeguarding valuable assets throughout the supply chain journey.

10. Oracle:

Oracle provides a robust suite of cloud-based applications to enhance supply chain visibility and efficiency through integrated solutions. With its Oracle Cloud Supply Chain Management (SCM), businesses can seamlessly connect various supply chain processes including planning, procurement, manufacturing, inventory management and logistics. This integration allows businesses to respond swiftly to changing market conditions and customer demands, improving overall operational agility.

One of the main features of Oracle SCM is its multitier supply chain visibility. This capability enables businesses to monitor product flow across their entire supply chain journey from suppliers to end customers. Businesses can detect and analyze disruptions in real time, allowing them to take proactive measures to mitigate risks. Oracle’s advanced analytics tools gather data from both internal systems and external sources to provide actionable intelligence that enhances decision-making.

Oracle SCM incorporates predictive analytics and IoT technologies to anticipate potential issues such as inventory shortages or delivery delays. This helps businesses optimize their logistics operations by improving service levels and reducing costs associated with inefficiencies. The logistics visibility software supports automated compliance processes, ensuring that businesses adhere to regulatory requirements seamlessly. For enterprises seeking a comprehensive solution that combines visibility with operational efficiency, Oracle is a great bet in the supply chain management landscape.

11. Pando:

Pando is an AI-powered logistics visibility platform that revolutionizes supply chain management through its unified fulfillment cloud. Designed for manufacturers and retailers, Pando streamlines the orchestration of both purchase orders and customer orders, enhancing service levels while reducing carbon footprints and freight costs. The platform uses advanced machine learning algorithms to optimize multi-modal transportation enabling users to manage complex logistics operations effortlessly.

One of Pando's key features is its dynamic rate forecasting, which utilizes historical and real-time market data to manage freight volatility. This allows the businesses to anticipate fluctuations in shipping costs, enabling more strategic decision-making. Pando’s 3D load planning functionality maximizes space utilization within trucks or containers, reducing waste and improving efficiency during loading processes.

The platform also emphasizes collaborative user experience, providing mobile applications that facilitate seamless communication between carriers and freight forwarders. This collaboration enhances shipment execution and ensures that all stakeholders are informed throughout the process. Pando integrates with existing systems, allowing for streamlined data flow across various functions from sales to inventory management.

Pando’s commitment to sustainability is evident in its backhaul optimization capabilities, which identify opportunities to fill empty space on return trips, minimizing empty miles. With its focus on agility and real-time visibility, Pando empowers businesses to build resilient supply chains that adapt quickly to changing market conditions. Pando stands out as a comprehensive solution for companies looking to enhance their logistics operations while achieving significant cost savings.

12. Blume Global:

Blume Global delivers an integrated approach to supply chain visibility through its innovative cloud-based platform, designed to manage transportation networks efficiently. The platform focuses on providing real-time insights into shipment statuses while optimizing logistics processes using advanced analytics. This allows organizations to monitor their supply chains dynamically, identifying bottlenecks and addressing issues before they escalate.

One of Blume Global's standout features is its management by exception system which alerts the users about potential opportunities and exceptions based on predefined business rules. This ensures that the users can focus on critical issues impacting their operations, thereby enhancing overall efficiency. Users can access a comprehensive dashboard that displays shipment statuses, exceptions, and a watchlist for hot shipments, improving customer service without the need for additional staff.

Blume Global emphasizes collaboration among stakeholders by enabling seamless communication between shippers, carriers and customers. This helps build transparency and trust throughout the supply chain, allowing everyone involved to stay informed about the status of shipments in real time.

The platform also supports extensive data integration, connecting with various transportation management systems to provide a holistic view of logistics operations. By leveraging real-time data, Blume Global empowers businesses to make informed decisions, driving operational excellence and enhancing customer satisfaction in an increasingly complex supply chain landscape.

Conclusion

Real-time transportation visibility platforms are crucial in modern logistics. They enable businesses to monitor and manage their supply chains with unmatched accuracy and speed. By using advanced technologies such as GPS, IoT and AI, these platforms provide live updates on the shipment status, enabling businesses to respond proactively to disruptions and optimize operations. The benefits of RTTVPs extend beyond mere tracking. They enhance customer satisfaction through transparency, reduce operational costs and facilitate informed decision-making. As supply chains become increasingly complex, the adoption of RTTVPs is not just advantageous but essential for businesses to gain a competitive edge in the market. Integrating these platforms into logistics strategies is a major step toward improving efficiency and resilience in supply chain management.

Frequently Asked Questions

1. What is a real-time transportation visibility platform?

A real time visibility platform is a solution that provides live updates on the location and status of shipments throughout the supply chain. It typically uses GPS and telematics data to track orders from departure to delivery. This enables businesses to optimize their logistics and improve customer satisfaction by providing accurate ETAs and real-time insights into their operations.

2. How do RTTVPs enhance supply chain efficiency?

RTTVPs enhance supply chain efficiency by offering real-time visibility into shipment status, which helps businesses quickly respond to disruptions such as delays or traffic congestion. This enables better decision-making, improved operational performance and reduced costs associated with logistics management, leading to a more efficient supply chain.

3. What features should I look for in an RTTVP?

When selecting a real time transportation visibility platform, consider features such as carrier connectivity, status and condition tracking, integration with existing business systems and advanced analytics capabilities. These features ensure comprehensive visibility and support for evolving business needs, enhancing overall supply chain management.

Komal Puri is a seasoned professional in the logistics and supply chain industry. As the AVP of Marketing and a subject matter expert at FarEye, she has been instrumental in shaping the industry narrative for the past decade. Her expertise and insights have earned her numerous awards and recognition. Komal’s writings reflect her deep understanding of the industry, offering valuable insights and thought leadership.

Let's Talk to Our Experts and Optimize Your Deliveries Today!

An expert from our team will reach out within 24 hours

Related resources