- Big & Bulky

Optimizing Big and Bulky Delivery: How to Improve Large-Item Fulfillment

Table of Contents

- Why Big and Bulky Delivery Breaks Traditional Routing Models

- The Dispatcher’s Dilemma: Constraints, Exceptions and Cost

- The Routing Toolkit That Actually Fits Big and Bulky Delivery

- Scenarios That Mirror Daily Reality

- What Changes When AI Powers Big and Bulky Delivery

- Implementation Playbook: Reduce Risk, Accelerate Time to Value

- KPIs That Prove Big and Bulky Delivery is Working

- FarEye's Unique Value Proposition: What Sets Us Apart

- Closing the Loop: Turn Doorstep Moments into Loyalty

- FAQs

Big and bulky delivery has become the real test of reliability as households outfit rooms with furniture, appliances and fitness equipment. A single missed slot can undo days of planning, frustrate customers and inflate costs. One powerful tailwind keeps pressure rising: in Q2 2025, U.S. e-commerce sales reached $292.9 billion and accounted for 15.5% of total retail, expanding the addressable last-mile with every quarter.

This story starts in the living room, not the loading bay. Families clear space, discard the old couch and plan an evening around delivery. When drivers arrive late or crews lack the right skills, disappointment lands at the doorstep. The mission is straightforward yet unforgiving: orchestrate every moving part so the moment feels effortless for the customer.

Why Big and Bulky Delivery Breaks Traditional Routing Models

Big and bulky shipments don’t behave like small parcels. Below are two core structural problems that traditional routing models struggle with:

Skill, Equipment and Dwell-Time Constraints

Routing tools not built for large-item needs assume each stop is similar. Big and bulky delivery involves items needing stair carry, lift-gate, assembly, haul-away, hookup or appliance setup. Crews must have special equipment and skills. Dwell time per stop varies wildly and is often under-estimated. Traditional models that ignore these constraints under-promise, over-deliver late and inflate costs.

Customer Expectations in Big and Bulky Fulfillment

Consumers expect more than a doorstep by evening. They want narrow delivery windows, often two-hour slots, pre-arrival notices, damage-free handling and real-time tracking. When customers order sofas, washers and treadmills, they expect professionalism, care and consistency. If the delivery lacks those qualities, brand trust erodes. Traditional models often fail chosen slots, lack visibility and can’t enforce service promises for fragile large items.

The Dispatcher’s Dilemma: Constraints, Exceptions and Cost

Dispatchers confront a puzzle that changes by the minute, not the day. New appointments arrive, customers shift time windows and traffic spikes without warning. Crews call out sick, a dock bay closes unexpectedly and one damaged carton forces a return. Without systems that understand constraints and react in real time, yesterday’s plan becomes today’s backlog.

Where costs creep in, every failed first attempt adds re-delivery miles, rescheduling overhead and customer support time. Idle crews waiting for elevators burn budget. Missed skill matching doubles dwell and compounds lateness. The right routing foundation contains these costs by preventing failure modes before trucks roll.

The Routing Toolkit That Actually Fits Big and Bulky Delivery

Each sub-capability below earns its keep when the calendar fills and the exceptions fly. Think of these as building blocks of a resilient, high-throughput plan.

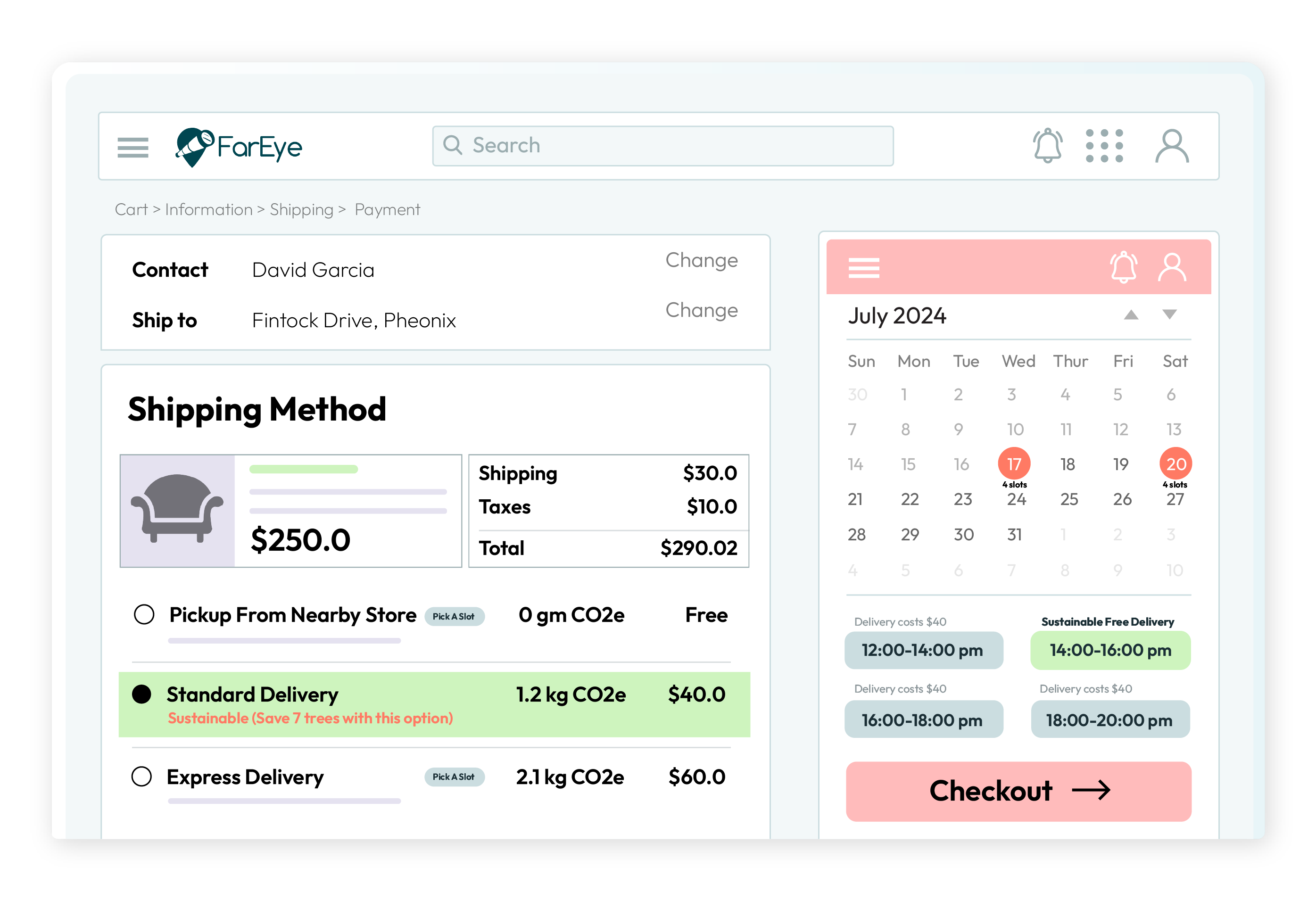

Slot Booking That Protects the Plan

Offer precise windows aligned to feasible routes and capacity, not generic all-day promises. Constrain slots by geography, promised cutoffs and crew workload so customer choice strengthens your plan rather than undermines it. FarEye’s Route Planning Software aligns promised ETAs with capacity and constraints, then optimizes accordingly.

Constraint-aware optimization, not just shortest paths

Encode vehicle capacities, item dimensions, lift-gate needs, skills, service times and building rules directly in the optimizer. FarEye’s platform factors driver schedules, multi-fleet models and delivery requirements to produce executable routes at enterprise scale.

Skill and Crew Pairing for Two-Person Deliveries

Pair assemblers and installers with drivers for complex items and schedule stairs or haul-away tasks explicitly. FarEye’s Big and Bulky Delivery software emphasizes skill-based team mapping and slot-based delivery to raise first-attempt success.

Real-Time Re-Optimization and Visibility

Plans age quickly on the road. Dynamic rerouting around traffic, overruns and no-shows keeps the day salvageable and customers informed. FarEye highlights real-time adjustments and branded tracking so operations stay proactive and customers stay confident.

Hybrid Fleet Decisions That Respect Margin

Blend owned, third-party and specialized carriers using cost- and capacity-aware allocation rules. The platform’s orchestration connects TMS, WMS and carrier systems into one control tower for consistent decisions.

EV- and Sustainability-Aware Planning

Consider charging stops, range limits and green delivery windows alongside standard constraints. Optimizing for emissions often reduces miles and dwell, tightening cost per stop while advancing sustainability goals.

Scenarios That Mirror Daily Reality

Each short example reflects situations dispatchers face weekly, spotlighting where routing intelligence changes the outcome.

Apartments on a Tight Elevator Schedule

Morning routes include three high-rises with strict freight elevator windows. Constraint-aware slot booking prevents stacking overlapping windows and the optimizer sequences floors to minimize elevator waits and dwell. A single reroute preserves the schedule when one building shifts its window by thirty minutes.

Washer-Dryer with Hookups and Haul-Away

The order requires water shutoff, venting and removal of the old unit. Skill tagging pairs a driver with an installer and ensures the truck carries the right fittings. Dwell time expands automatically, protecting downstream ETAs without manual edits.

Suburban Sofa Plus Stair Carry

Customer notes indicate a narrow staircase and a tight corner. The plan flags a two-person crew, pads dwell by twelve minutes and sequences the stop before the crew’s mandated break. An accident on the beltway triggers re-optimization, shifting a later, low-sensitivity stop to another team.

Kitchen Cabinet Sets, Multi-Stop Consolidation

Several shipments destined for one neighborhood are consolidated into a dense micro-tour. A crew qualified for delicate cabinetry gets those stops, reducing damage risk and first-attempt failures. FarEye highlights a cabinet manufacturer case improving delivery success to 73%, reinforcing the value of crew and skills alignment.

What Changes When AI Powers Big and Bulky Delivery

Modern platforms use AI to squeeze latency from decision-making and surface better choices during planning and execution. When discussed with customers, four improvements recur most often.

- Sharper ETA accuracy under real-world volatility. Machine learning models combine historical dwell patterns, building traits and traffic behaviors to forecast realistic stop durations. Organizations deploying FarEye’s big and bulky delivery report tighter ETA windows and materially fewer surprise overruns.

- Higher first-attempt success through smarter slotting. AI-assisted slot presentation reflects true capacity and constraints, nudging customers toward feasible windows. Teams report meaningful uplifts in first-attempt success rates once slotting and skills are optimized together.

- Cleaner dispatcher workload and faster exception handling. Instead of rebuilding routes by hand, dispatchers approve system-proposed adjustments as conditions change. The result is less rework, better route density and a calmer control room on peak days.

- Lower cost per stop without blunt service cuts. Route density improves as infeasible combinations disappear from the plan. Hybrid fleet assignment and real-time swaps reduce reattempts and empty miles, improving unit economics sustainably.

Implementation Playbook: Reduce Risk, Accelerate Time to Value

A thoughtful rollout secures early wins while building organizational confidence. Each step below deserves a sprint of its own.

Start with Data Fidelity

Normalize addresses, time windows, item dimensions and skills. Validate dwell assumptions by product type, property type and service steps. Good data unlocks algorithmic precision and prevents avoidable failures later.

Pilot the Right Slice of Business

Choose a territory with representative density, building types and order mix. Set baseline metrics first-attempt delivery rate, on-time delivery, cost per stop and route density so gains are visible and credible to frontline teams.

Train Dispatchers and Crews to Operate Deliberately

Hands-on practice with scenario playbacks cements trust in re-optimization and slot logic. Crews should know how exceptions flow to dispatchers and how updates reach customers.

Integrate Upstream and Downstream Systems

Connect OMS, WMS and TMS so promises at checkout reflect reality in planning. Ensure proof-of-delivery artifacts, photos, checklists and signatures flow back to analytics and customer care.

Instrument Relentlessly and Close the Loop

Review exceptions daily, refine dwell models weekly and tune slot rules monthly. Treat routing like a living system that gets smarter with each iteration.

KPIs That Prove Big and Bulky Delivery is Working

Each metric below connects directly to customer experience and unit economics. Track them visibly and improve them methodically.

- First-attempt delivery rate. The single strongest indicator of end-to-end orchestration quality; improving it compounds margin and satisfaction.

- On-time performance within promised windows. Use realistic windows, then defend them with re-optimization and exception workflows when reality shifts.

- Average dwell time by product and property type. Precision here protects ETAs and route density; inaccurate dwell inflates misses downstream.

- Cost per stop and miles per successful stop. Watch both, since increasing density can mask reattempt costs; success-weighted miles give a clearer picture.

- Customer reschedule rate and reschedule lead time. Lower rates reflect better slot design, clearer pre-arrival communication and trustworthy ETAs.

FarEye's Unique Value Proposition: What Sets Us Apart

When you choose a platform to improve big and bulky delivery, you need more than generic routing. FarEye delivers a suite of capabilities built specifically for the most demanding requirements. Here are the core differentiators:

| Feature | Why it Matters for Big & Bulky Delivery |

| Constraint-aware Planning | FarEye encodes all key limitations, crew skills, equipment needs (stair carry, lift gate, hookup), building access and item dimensions so that routes are not just feasible, but optimized for real conditions rather than idealized assumptions. |

| Skill and Crew Pairing | More than matching a driver to a route. FarEye matches crews with necessary skills (e.g., installers, assemblers) to specific delivery tasks. By doing so, first-attempt success rises and repeat visits drop sharply. |

| Real-time Reoptimization | Once routes are dispatched, real-world chaos begins: traffic jams, schedule shifts, customer changes. FarEye’s platform continuously adjusts routes in flight, preserving SLA adherence and minimizing delay costs. |

| Control Tower Visibility | A unified control tower gives dispatchers and leaders full visibility over all orders, vehicles, crews and statuses. You see exceptions early, act proactively and maintain accountability across all moving parts. |

| EV and Green-slot Nudging | With sustainability now a key expectation, FarEye includes features for EV routing, charging station mapping and nudges for green delivery windows. You can balance cost, emissions and customer experience with real metrics. |

Closing the Loop: Turn Doorstep Moments into Loyalty

Big and bulky deliveries will always involve variables you cannot fully control, from traffic to building access quirks. The advantage comes from how quickly your plan senses change, reshapes itself and communicates confidently. With the right foundation, AI-assisted slotting, constraint-aware optimization, real-time re-optimization and a unified control tower, dispatchers convert complexity into dependable experiences.

FarEye’s platform was designed for exactly this challenge, pairing sophisticated optimization with practical tools that crews and customers actually use. If your teams are ready to transform big and bulky fulfillment into a competitive advantage, the path forward starts with smarter routing and a tighter promise-to-plan-to-doorstep loop.

FAQs

What is a big and bulky delivery?

Big and bulky delivery refers to the shipment of large, heavy or awkward items furniture, appliances and fitness equipment, that require special handling, extra labor and more complex logistics. These orders often demand lift gates, two-person crews, room-of-choice placement and adherence to constraints such as access, stair carries and scheduled appointments.

How do you improve big and bulky delivery first-attempt success?

First-attempt success improves by matching skills and equipment to delivery tasks (e.g., installers, lift gates), using accurate dwell-time estimates, booking slots that reflect capacity and enabling real-time route adjustments. Visibility tools for exceptions and proactive communication with customers also reduce failures and re-delivery costs.

What’s the difference between white-glove and room-of-choice?

Room-of-choice delivery means the carrier places the item in the customer’s specified room, provided there’s a clear path without unpacking or setup. White-glove delivery adds premium services: unpacking, setup or installation, removal of packaging and often haul-away or old item removal. It requires specialized crews and higher fees.

How do dynamic delivery slots reduce reschedules?

Dynamic delivery slots present only feasible time windows based on current load, vehicle capacity, crew skills and route constraints. Customers choose from these realistic slots rather than inflexible promises. As real-time factors change (traffic, crews), the system re-optimizes and offers alternate slots, cutting down on rescheduling and missed windows.

How do you forecast dwell time for large items?

Forecasting dwell time involves analyzing historical data by product type, property type (stairs, elevator, apartment), required service steps (hookups, haul-away, assembly), crew skill and other constraints. Machine learning models or statistical tools use these data points to predict realistic service durations, improving schedule accuracy and reducing downstream delays.

Sources:

https://www.census.gov/retail/ecommerce.html

Premier American cabinet manufacturer improves delivery success rate to 73% with FarEye | FarEye

Komal Puri is a seasoned professional in the logistics and supply chain industry. As the AVP of Marketing and a subject matter expert at FarEye, she has been instrumental in shaping the industry narrative for the past decade. Her expertise and insights have earned her numerous awards and recognition. Komal’s writings reflect her deep understanding of the industry, offering valuable insights and thought leadership.

Let's Talk to Our Experts and Optimize Your Deliveries Today!

An expert from our team will reach out within 24 hours

Related resources