- Vehicle Routing

Optimize Route Planning to Cut Costs Without Sacrificing Delivery Speed

Table of Contents

- The Hidden Waste in Your Route Optimizer Today

- How a High-Impact Route Optimizer Thinks Differently

- Levers to Optimize Route Without Slowing Down Delivery

- Implementation Judgment Calls (Where the Expert Deliberates)

- Risks and Smarter Fallbacks

- Key Metrics That Reveal if You’re Winning

- Ready to Pilot Smarter Routing and See Real ROI?

A dispatcher stared at the map screen, watching a truck detour around unexpected congestion, adding 20 extra miles, burning precious fuel and inching closer to a missed SLA. That moment reveals the conflict at the route planner’s desk: between cutting costs and preserving delivery speed.

To solve it, you need to optimize route logic smartly, using a capable route optimizer that understands real constraints, trade-offs and hidden inefficiencies. Let’s get inside the reasoning, see how to balance competing priorities, learn pitfalls and see how an AI/ML-powered routing system embodies these principles in real enterprise use.

The Hidden Waste in Your Route Optimizer Today

Even well-staffed fleets suffer from invisible leakage. Identifying it is your first step.

The cost you can’t see (idle time, dead mileage, rerouting churn)

- Idle/Dwell Time: Trucks waiting at loading docks, staging zones or gates add no value but inflate driver costs and extend route time.

- Dead Mileage: kilometers traveled with no stops (returning to depot, repositioning) that are rarely captured in naive planning.

- Rerouting Churn: Each mid-route swap or insertion causes extra detours and inefficiency.

These invisible wastes can amount to 6 to 13% of your baseline route cost if unchecked.

Why Shortest Path Heuristics Fail Under Real Constraints

A pure nearest neighbor or simple greedy algorithm may minimize raw distance, but it ignores constraints like time windows, Hours of Service (HOS), driver breaks, load capacities, traffic, EV range and required buffer times. In practice, shortest-path routing often forces violations, SLA misses or excessive slack to compensate.

How a High-Impact Route Optimizer Thinks Differently

A high-performing system is more than a map engine; it reasons about cost, constraints and trade-offs.

Objective Blending (Time, Fuel, Delay, Penalty), Not Single Metric

Rather than minimizing just distance or time, a robust route optimizer optimizes a combined cost function. Fuel and maintenance cost per km, driver wage/time cost, delay penalties (for missing OTIF/windows), slack cost and reopt penalty. Tuning these weights lets you lean toward cost efficiency or delivery consistency.

Constraint Hierarchy and Soft vs Hard Constraints

- Hard Constraints: Non-negotiables (HOS limits, vehicle capacity, legal breaks)

- Soft Constraints: Preferred rules (time windows, sequence preferences) which may be violated at a penalty.

A strong route optimizer respects hard rules while giving you flexibility on soft ones under controlled penalty.

Predictive Routing (Traffic, Delay Hot Zones) vs Reactive Routing

Rather than reacting purely to real-time traffic, systems embed predictive models (historical slow zones, variance) so routes anticipate congestion. Real-time deviations only trigger reopt when variance exceeds thresholds, reducing excessive churn.

Architectures: Full Reopt vs Local Adjustments vs Partial Reopt

When something changes mid-route, good route optimizers can:

- Recompute the whole route (full reopt),

- Adjust a local segment (partial reopt),

- Or only reassign a handful of stops (insertion/swap).

Choosing wisely avoids overdisruption.

Trade-off Knobs You Should Control (Slack, Buffer, Churn Limits)

Essential configuration levers include:

- Slack/buffer per stop or segment

- Maximum churn/change threshold for reoptimization

- Delay tolerance threshold to trigger reopt

- Penalty weights for window slips or reassignments

These knobs govern how aggressively your system sacrifices stability for cost gains.

Levers to Optimize Route Without Slowing Down Delivery

These are tactical moves the best fleets use, not generic platitudes.

- Joint Route + Speed Tuning: Sometimes Slower is Cheaper But Still Meets SLA

Fuel consumption isn’t linear with speed. A slightly slower but smoother route may save cost while still meeting delivery windows. The optimizer should choose speeds per segment, not treat all speeds equally. - Zoned Clustering: Keep Local Loops Tight, Minimize Crossovers

Segment your service area into zones and plan each vehicle’s cluster. This reduces cross-zone "leapfrog" routing and confines inefficiencies locally. - Flexible/Soft Time Windows (How Much Flexibility to Allow)

Lock only premium deliveries to fixed windows; allow other stops ± 5 or ±10 minutes slack as a soft window to give the optimizer breathing room. - Buffering Strategies Where Slack Helps Most

Don’t uniformly pad all stops. Add buffers before high-variance segments (rush hour zones, key intersections). Smart placement of slack beats blanket padding. - Smart Vehicle Assignment and Load Balancing

Assign based on capacity, driver skills (if multi-skilled) and route density. Avoid overloaded vehicles or idle ones: balanced assignment lets routes converge nearer to optimal. - Use Of Premium/Toll Roads When They Pay Back

In high-congestion zones, paying a toll or using express lanes can save the delay cost exceeding toll expense. The optimizer should weigh it. FarEye supports routing that factors in tolls and preferred roads. - Triggered Reoptimization: When To Reroute, When To Stick

Set thresholds (e.g., delay > 10% or > 5 stops affected) before reoptimizing. Minor deviations may be better absorbed than triggering a disruptive reroute.

Implementation Judgment Calls (Where the Expert Deliberates)

Even the smartest optimizer needs judgment.

- What to Pilot First (Region, Subset)

Pick a dense urban area or problematic zone where gains are highest. Start with a subset of 20–50 vehicles, not the full fleet. - Data Readiness Checks (Address Quality, Travel Time Distributions)

Ensure geocoding accuracy, historic travel time distributions by time of day, stop dwell time data and known traffic variance. - Calibration Phases: Tuning Weights, Simulating Variations

Run your past routes in shadow mode. Test multiple weight sets, measure deviation and compare outcomes. Use scenario simulation to stress-test. - Reoptimization Frequency Trade-off (Too Frequent → Chaos, Too Slow → Missed Opportunities)

Avoid reoptimizing on every small drift. Limit reopt intervals (e.g., every 30 min or only when thresholds hit). Also, limit changes to a fraction of the route. - How Much Driver Override to Allow

Allow small deviations but monitor them. Feed driver decisions back into the system to learn local heuristics and adjust the model. - Governance and Human-in-the-Loop Checks

Establish thresholds where a human dispatcher must approve reoptimization. Log exceptions, review weekly and adjust strategy accordingly.

Risks and Smarter Fallbacks

Recognizing risk and fallback strategies is part of expertise.

- Over-optimization, Fragility and Veering off Schedule Get You Stuck

If routes are too tight, small disruptions cascade. Always maintain a minimal buffer so small delays don’t cascade. - Route Churn: Too Many Mid-route Changes Break Driver Trust

Frequent reassignments annoy drivers. Cap churn levels; prefer route stability when gains are marginal. - Misestimated Traffic/Anomalies

Accidents, weather and special events may break models. When confidence is low, fall back to simpler, safer routing logic. - Drivers Using Local Heuristics Vs an Optimized Plan

Drivers may prefer familiar shortcuts. Build feedback loops: monitor deviations, allow periodic local adjustments and retrain the optimizer over time. - Architecture/Latency Bottlenecks (Solve Scale Issues)

Large fleets require partitioning, parallel computing, incremental optimization, not full global reopt each time. Design architecture for low-latency, incremental updates.

Key Metrics That Reveal if You’re Winning

Measure to see if your route optimization is paying off.

- Cost per Deliver/Cost per Km: Primary financial metric

- On-time Ratio/SLA Attainment/OTIF: Service success metric

- Route Deviation (Actual vs Plan): Shows drift or model mismatch

- Reopt Count and Scope: How often you trigger reopt, how many vehicles are impacted

- Stop Density/Route Compactness: How tightly packed your routes are

- Fuel/Maintenance Cost Trends Over Weeks/Months: Operational health

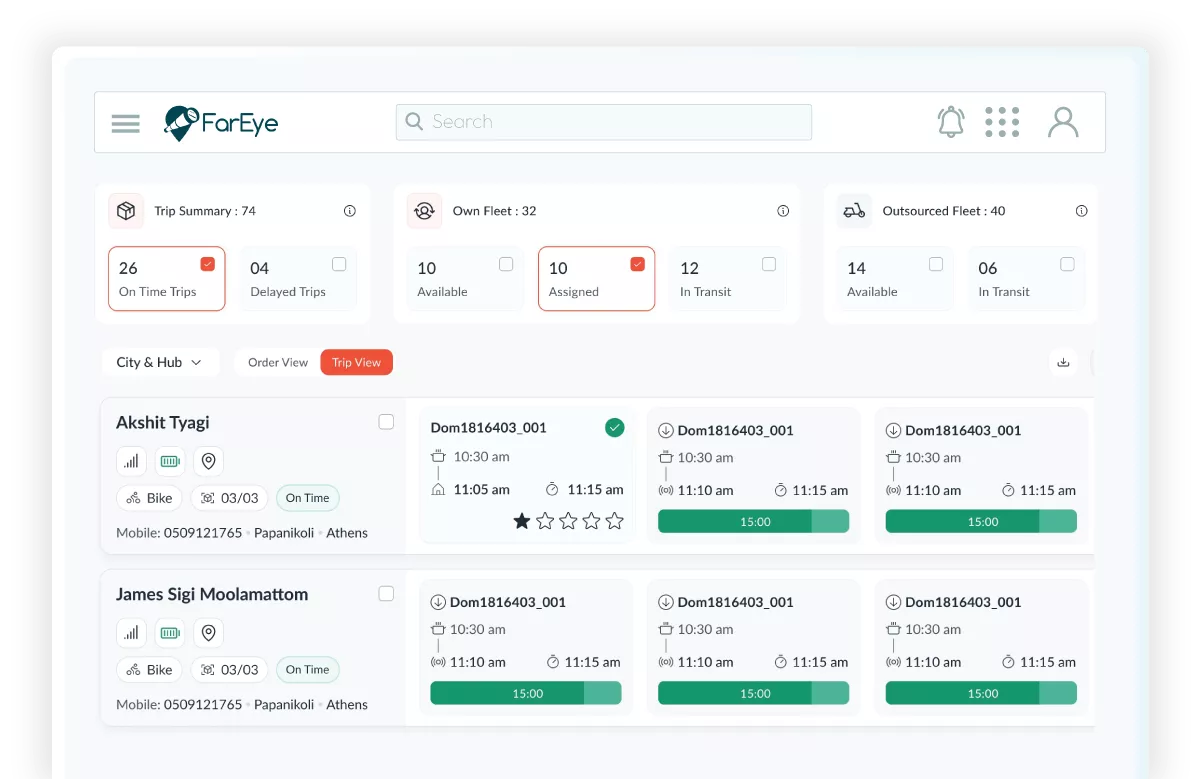

Track these weekly in dashboard form and flag regressions early.

Ready to Pilot Smarter Routing and See Real ROI?

You can optimize route planning to cut costs without sacrificing delivery speed. This is possible only if your system reasons in a multi-dimensional cost space, controls reoptimization, tunes slack thoughtfully and accepts human feedback.

Begin with a pilot: run your current routes in shadow mode, measure hidden waste, calibrate weight sets and gradually shift to a route optimizer. Use a trade-off worksheet to log how cost vs time weights evolve. Track your key metrics weekly and refine.

Want help designing that pilot? Seeing how FarEye’s AI/ML routing can fit your fleet scale.

Source:

Digitizing mid- and last-mile logistics handovers to reduce waste | McKinsey

Raunaq Singh leads Product Marketing at FarEye and is a subject matter expert in last-mile delivery and logistics technology. With a deep focus on AI-led innovation, he works at the intersection of product strategy, market intelligence, and storytelling to shape how enterprises think about delivery orchestration and customer experience. His writing reflects a strong understanding of both emerging technologies and real-world operational challenges.

Let's Talk to Our Experts and Optimize Your Deliveries Today!

An expert from our team will reach out within 24 hours