- Route

Why Data-first Logistics Route Planners Transform Supply Chain Visibility

Table of Contents

- From Friction to Clarity: The Visibility Gap Dispatchers Face

- What Makes a Logistics Route Planner Truly “Data-First”?

- How a Data-first Routing Logistics Approach Enhances Visibility

- What Supply Chains Unlock When Visibility Improves

- Core Pillars of a Best-in-Class Logistics Route Planner

- Challenges and Real-World Tradeoffs (From the Dispatcher Lens)

- How to Begin Your Data-first Journey in Routing Logistics

- Turn Data into Visibility: Get Started Now

Every morning, a U.S. dispatcher stares at a dispatch sheet cluttered with half-assigned orders, shifting windows, and driver gaps. That chaos is more than operational noise; it’s a symptom of blind spots in your supply chain’s nervous system.

Companies that invest in data-first logistics route planners routinely achieve over 40% on-time delivery rates, reduce empty miles, and regain visibility across fleet operations. In fact, the global route optimization and planning market is projected to reach USD 7.6 billion in 2025, with enterprise adoption driving much of that growth.

Let’s walk through how placing data at the core of routing logistics doesn’t just refine routing; it redefines supply chain visibility itself.

From Friction to Clarity: The Visibility Gap Dispatchers Face

The Fog of a Disconnected System

You may juggle a TMS, GPS modules, manual spreadsheets, and phone calls, but none operate on a unified, real-time data fabric. That disconnection means by the time a delay trickles through, it’s already too late.

The Downside of Fixed Plans in a Dynamic Day

Your routes may be optimized on paper, but traffic snarls, canceled orders, or last-minute add-ons break them apart. When a driver is forced to take a 20-minute detour and you lack visibility, downstream deliveries suffer.

Invisible Capacity, Hidden Inefficiency

Without per-vehicle, per-stop load visibility, you risk underutilizing trucks or leaving last-minute gaps. That means more trips, more cost, more risk.

These blind spots are more than nuisances in the U.S.; failed first delivery attempts cost carriers approximately $17.2 per order in added handling, fuel, and service costs. Data-first routing flips that paradigm. Instead of patching visibility, it embeds it.

What Makes a Logistics Route Planner Truly “Data-First”?

Data as Foundation, Not an Add-on

A data-first logic treats historical records, IoT/telematics feeds, external signals (weather, traffic APIs), and exception logs as fuel, not friction.

Three Critical Data Strata:

- Historical Data: Past delivery times, dwell durations, and route performance

- Real-time Streams: GPS feeds, live traffic, sensor data (e.g., vehicle load, temperature)

- External Context: Weather forecasts, road closures, event calendars

A powerful data layer fuses those inputs, contextualizes them, and feeds smart routing decisions.

Closed-loop Intelligence: Learning from Outcomes

Each route execution becomes a feedback point. Did a driver get delayed unexpectedly? That anomaly is fed back into machine learning models, which adjust future predictions. Over time, the system “gets smarter,” reducing surprises.

Multi-objective Optimization, Not Single-metric Trickery

A data-first logistics route planner balances distance, time, load, cost, driver breaks, regulatory compliance, and priority orders simultaneously, not by toggling weights manually, but by learning from past tradeoffs.

How a Data-first Routing Logistics Approach Enhances Visibility

With a data-first routing logistics approach, you gain a continuously updating view of every route leg, enabling you to detect disruptions early and recalibrate on the fly.

Real-time Map of Execution

Instead of waiting for status calls, you see actual vehicle progress, deviations, delays, and can probe the cause (traffic, breakdown, misroute).

Proactive Alerts and Exception Handling

Because you see data early (e.g., a route segment is backing up), you get triggered alerts to reroute, reassign, or preemptively inform downstream stops.

Confidence-scored ETAs

Rather than fixed ETAs, each route leg comes with a confidence score or range. For example, “Package B: ETA 2:15 pm ±10 min (87 % confidence).” That transparency helps customer service teams set expectations.

Load and Capacity Insight Per Vehicle

You know not just where a driver is, but how full they are, which stops remain unassigned, or whether additional small orders can be merged in right up to dispatch.

Supply Network Lens

Data-first route optimization software aggregates across hubs, depots, and fleets. You view systemic bottlenecks, e.g., “Hub A has 20% spare capacity but trucks returning half-empty.” That visibility enables strategic shifts (rebalancing, zone adjustments).

What Supply Chains Unlock When Visibility Improves

Once supply chains achieve deeper visibility, they unlock the ability to pivot proactively, coordinate across functions, and convert insight into competitive advantage.

Decision Shift: Detect → Decide → Act

Instead of firefighting every delay, you forecast potential breaks and decide on reroutes proactively. Visibility becomes a decision lever, not just a reporting tool.

Harmonized Functions

Operations, customer service, sales, and executives see the same supply chain picture. Urgent reroute? CS can message customers early; leadership can assess macro trends.

Scale Without Chaos

As your order volume rises, visibility acts as your “central nervous system.” You can onboard more routes, vehicles, or regions without losing coherence.

Risk Resilience

When a highway closes or weather strikes, visibility lets you spin up alternative routes in minutes, reducing cascading failures.

Brand Integrity and SLA Enforcement

With transparent ETAs and reliable execution, you reduce failed deliveries and customer complaints. Visible transparency bolsters credibility in B2B and B2C alike.

Core Pillars of a Best-in-Class Logistics Route Planner

At the foundation of every high-performing dispatch system are core pillars that ensure your logistics route planner delivers not just paths but trustworthy, actionable visibility across your network.

Scalable, Low-latency Data Architecture

Your platform must ingest live streaming data, merge large historical stores, and respond quickly. Latency kills visibility.

Routing Engine and AI/ML Layer

Beyond classic heuristics, the route solver must incorporate AI to predict durations, learn driver patterns, and adapt constraints dynamically. (FarEye, for example, incorporates AI-first routing with over 100 constraints.

Reoptimization and Dynamic Rerouting

When deviations occur, the planner must recompute routes mid-operation, not wait for the next day or manual refresh.

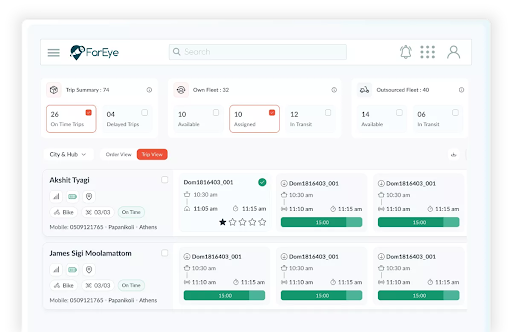

Visibility Dashboard and Alerts Module

A dispatcher UI with map layers, stop status, heatmaps, and alert panels is essential to transform raw data into action.

Deep Integrations

You need seamless connectivity with TMS, WMS, OMS, telematics, and partner APIs. Data siloes defeat the data-first premise.

Governance, Data Quality and Trust

Data-first demands high quality: address validation, sensor calibration, anomaly detection, drift monitoring, or you get garbage in, poor routing out.

Challenges and Real-World Tradeoffs (From the Dispatcher Lens)

While data-first routing logistics unlocks visibility, dispatchers must still contend with real-world tradeoffs balancing computation speed, human judgment, and unpredictable field constraints under pressure.

Complexity Overload

Too many constraints or overly ambitious AI tweaks can slow route generation. You must balance precision with runtime.

Edge Cases and Manual Overrides

Some conditions, VIP orders, and last-minute emergencies require human override. A flexible system must allow safe intervention without breaking visibility.

Change Management

Dispatchers used to Excel or local maps may resist a data-first shift. Training, transparency, and trust-building are key.

Data Gaps and Quality Drifts

Missing sensor data, stale traffic feeds, or unvalidated addresses can erode trust rapidly. You must constantly monitor data health.

How to Begin Your Data-first Journey in Routing Logistics

Starting a data-first routing logistics journey means first assessing what you have, then layering in structure, tools, and adoption in a way that delivers visibility.

Audit Your Data Landscape

Catalog all sources: historical logs, GPS devices, traffic APIs, and order systems. Identify gaps or stale feeds.

Pilot a High-impact Region

Start with one geography or one depot. Use data-first routing there, test visibility, refine models, then expand.

Choose a Partner or Build Smartly

You can build in-house, but solutions like route planning software already embed AI/ML, dynamic rerouting, and integrations. The faster you realize visible benefits, the sooner trust spreads.

Map Key Metrics and Dashboards

Define OTIF, route deviation, empty-miles percentage, and reassign rate. Feed them into your dashboard as live KPIs.

Train Dispatchers and Enforce Trust

Onboard them by showing how visibility helps, not by mandate. Let them see logistics route planner suggestions, override safely, and learn how data improves daily.

Iterate and Refine

As you gather performance data, reweight models, refine constraint sets, and expand into more complex routing zones.

Turn Data into Visibility: Get Started Now

Visibility in supply chains isn’t a luxury; it’s the foundation that enables precision, agility, and growth. Traditional routing systems treat data as an afterthought; a data-first logistics route planner treats it as the battery behind the engine. The difference isn’t incremental; it’s transformational.

With FarEye’s AI-powered routing, real-time reoptimization, and per-vehicle load insights, you don’t just see your operations; you control them. Organizations like yours can move from reactive dispatch to proactive command. Let visibility drive choices.

Sources:

https://www.futuremarketinsights.com/reports/route-optimization-planning-software-market

https://www.statista.com/statistics/973182/last-mile-delivery-average-cost/

Raunaq Singh leads Product Marketing at FarEye and is a subject matter expert in last-mile delivery and logistics technology. With a deep focus on AI-led innovation, he works at the intersection of product strategy, market intelligence, and storytelling to shape how enterprises think about delivery orchestration and customer experience. His writing reflects a strong understanding of both emerging technologies and real-world operational challenges.

Let's Talk to Our Experts and Optimize Your Deliveries Today!

An expert from our team will reach out within 24 hours