- Route Optimization

Best Route Planner for Delivery Drivers to Revolutionize Last-Mile Deliveries

Table of Contents

- Why Long-haul Routing Breaks Plans and How to Design for it

- The Constraint Set You Cannot Ignore

- Compliance by Design Beats Compliance by Audit

- AI in Trucking Logistics Software: Reliable ETAs and Robust Choices

- Multi-day Routing: Plan the Tour, Not the Day

- Reduce Idling, Truck Stacking and Empty Backhaul

- Co-mingling Loads Without Violating Promises

- Backhaul by Design: Match Lanes, Then Match Freight

- Fuel and Charging Strategy That Respects the Map

- From Fixed Plans to Living Execution

- What Great Long-haul Dashboards Look Like

- KPIs That Prove the Program Works

A winter front rolls across I-80 and the phones light up. Drivers face black ice, a bridge closure and a missed fuel stop. Your customers still expect a confirmed ETA, while your board expects fewer empty miles this quarter.

That is the daily tension long-haul teams feel, balancing safety, cost and service when the road keeps changing. The stakes are high. The latest American Transportation Research Institute analysis places the average U.S. trucking cost at $2.260 per mile, a reminder that every unplanned detour, detention or idle minute shows up in the margin.

AI-driven trucking logistics software helps you anticipate, not just react. It turns volatile conditions into structured decisions by blending road restrictions, driver hours, fuel and rest planning and multi-day constraints into one plan you can trust.

Below is a pragmatic playbook on what matters, how to operationalize it and where AI provides leverage when miles stretch long.

Why Long-haul Routing Breaks Plans and How to Design for it

Long-haul networks stretch across jurisdictions, weather systems and infrastructure bottlenecks, so the plan you publish at 6 AM rarely meets the road unchanged. ATRI’s annual bottleneck maps show persistent slowdowns around freight-significant interchanges, making timing fragile before the first stop.

Logistics software for trucking must therefore start with resilience: planning routes that assume road work, lane closures, tunnels, bridges, narrow roads and variable speeds will test timing. It must convert uncertainty into buffers that protect promised delivery windows without creating unnecessary slack that drives up cost.

The Constraint Set You Cannot Ignore

Every dispatcher recognizes the four constraint pillars. Good trucking software for logistics treats them as first-class citizens, not afterthoughts.

- Order Parameters

Pickup and delivery windows, height restrictions and truck size limits affect what can ride together and in what sequence. - Road Parameters

Tunnels, bridges, seasonal weight restrictions, road work and closures force legal, safe paths and change ETAs. - Vehicle Parameters

Height, length and width determine route eligibility; vehicle type determines where you can travel and dwell. - Driver Parameters

Department of Transportation hours-of-service, planned fuel stops and rest stops must be embedded, not bolted on.

When these inputs live inside the optimizer, trucking logistics software can build viable multi-day plans instead of printable wish lists.

Compliance by Design Beats Compliance by Audit

Hours-of-Service rules define legal drive time, required breaks and split sleeper options. Trucking logistics software that encodes HOS logic prevents illegal schedules before they leave the screen, instead of flagging violations after the truck departs.

A route that places a driver’s 30-minute break near a low-cost fuel stop, with safe parking and facilities, respects humans and margins simultaneously. FMCSA guidance makes those guardrails non-negotiable; your tools should make them effortless.

AI in Trucking Logistics Software: Reliable ETAs and Robust Choices

Machine learning matters when variability dominates. Trucking logistics software can learn travel-time patterns by corridor, hour and season, then suggest routes that are slightly longer but more reliable under snow or construction.

Over time, the model learns the penalty of specific interchanges and ramps, so dispatchers get realistic ETAs, not optimistic lines. FarEye’s AI-based routing uses real-time visibility plus historical patterns to anticipate delays, then re-sequence or reroute while preserving contractual delivery windows.

Multi-day Routing: Plan the Tour, Not the Day

Long-haul planning fails when tools only schedule Day One. Trucking logistics software must schedule multi-day tours with legal rest periods, overnight parking and regional curfews baked in.

FarEye’s truck routing explicitly supports multi-day planning, ensuring driver hours compliance and realistic overnight stops without breaking SLAs. That lets allocators confirm appointments with confidence instead of padding time to compensate for brittle plans.

Reduce Idling, Truck Stacking and Empty Backhaul

Three silent killers of long-haul economics driver idling, yard-level truck stacking and empty backhaul hide inside daily variance. Trucking logistics software combats them by:

- Sequencing gate arrivals to avoid yard congestion,

- Smoothing handoffs so drivers roll on time and

- Co-mingling compatible loads to fill the return leg.

FarEye’s optimization factors order, vehicle and road parameters together so your plan actively avoids dwell traps and designs backhauls as part of the outbound plan, not as an afterthought.

Co-mingling Loads Without Violating Promises

Shippers prefer dedicated capacity and honored time windows. Carriers prefer high utilization. Trucking logistics software aligns both by co-mingling loads only when height, weight and truck size restrictions fit and when delivery windows remain intact.

With the right optimization model, you can combine compatible orders heading along the same corridor, respect bridge clearances and still meet retail appointment times at the dock. FarEye’s engine evaluates order parameters and road restrictions simultaneously, which keeps co-mingling smart, not risky.

Backhaul by Design: Match Lanes, Then Match Freight

Empty miles are a tax on every decision. Trucking logistics software should forecast likely backhaul availability by lane and day, then propose outbound commitments that keep trailers full both ways.

Dispatchers win when the plan pairs markets with predictable returns rather than chasing one-way revenue. FarEye’s planning supports multi-stop routing and dedicated capacity models, improving utilization for captive fleets while keeping commitments to high-value cargo.

Fuel and Charging Strategy That Respects the Map

Fuel is controlled both by price and by where the route allows safe access. Trucking logistics software should stage fuel stops in low-friction locations that align with legal breaks, parking availability and service quality.

For mixed or emerging fleets, route planning must evolve toward energy-aware choices, including gradients, weather and charging locations for alternative powertrains. FarEye’s vehicle-type logic and road-parameter awareness make these choices practical within one plan.

From Fixed Plans to Living Execution

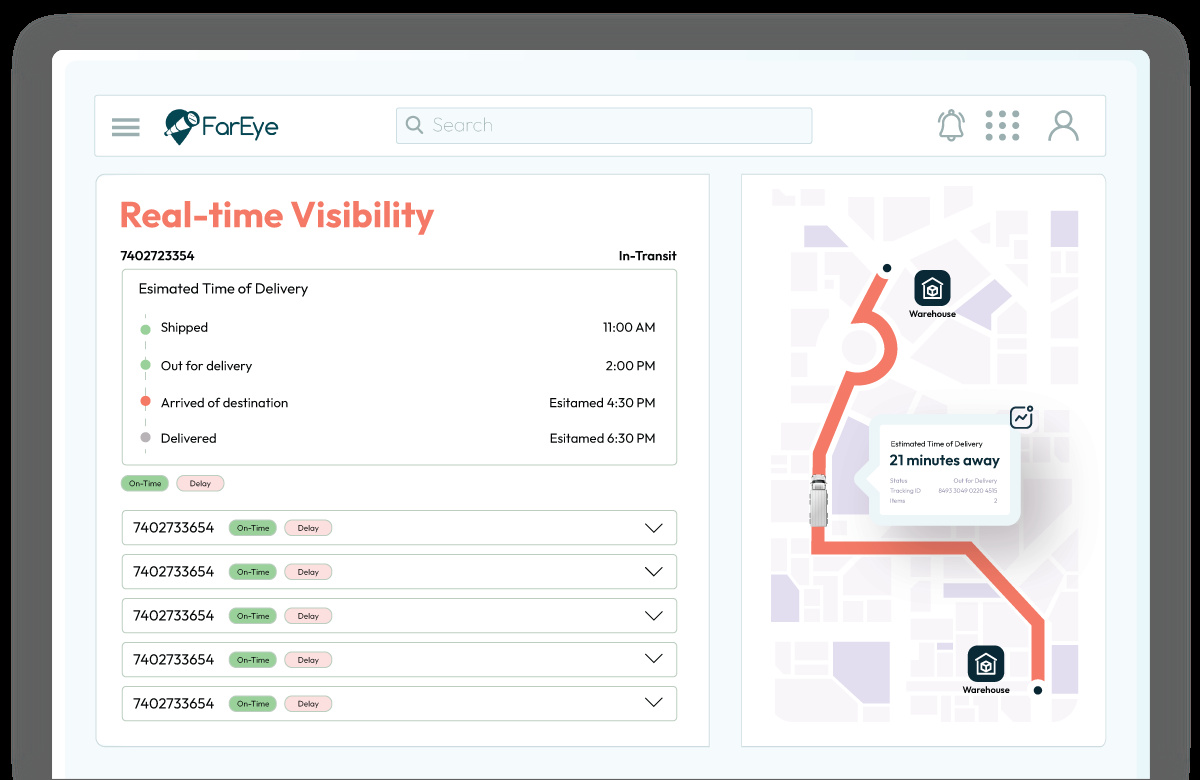

Plans die without visibility. Trucking logistics software must stream GPS, traffic and weather into a single operational picture, then notify allocators when a corridor turns red.

FarEye provides real-time visibility and predictive ETAs so you can resequence stops, switch drivers or rebook time windows proactively. Customers receive accurate status, while your team preserves service without scheduling chaos.

What Great Long-haul Dashboards Look Like

Dashboards for dispatch should surface the variables that move profit and risk. Your trucking logistics software should highlight:

- Cost Drivers: Fuel per route, labor per delivery and maintenance risk by asset.

- Utilization Signals: Miles per stop, empty miles and trailer turn times.

- Compliance Posture: Break adherence, HOS thresholds and route legality by segment.

- Service Health: ETA confidence, dock appointment risk and dwell outliers.

FarEye’s route and execution views bring these elements together so route managers can intervene once, not everywhere.

KPIs That Prove the Program Works

Teams succeed when they measure the few numbers that predict all others. Your trucking logistics software should help you track:

- Empty mile ratio and backhaul utilization on core lanes.

- ETA accuracy and on-time adherence against appointment windows.

- Fuel per route and labor per delivery, trended by corridor and season.

- Driver idling and yard dwell, especially at high-volume facilities.

- Compliance events and rest-break alignment with scheduled stops.

These indicators connect daily routing to financial performance, which matters more as costs per mile remain elevated in the industry.