- Logistics

Scaling Complex Operations? Logistics Route Planning is the Key to Predictability

Table of Contents

- What is Logistics Route Planning?

- The Dispatcher’s Pain: Why Scale Breaks Predictability in Logistics Routing

- Logistics Route Planning Software as Your Predictability Engine

- Architecture and Algorithms: How to Build Logistics Routing at Scale

- FarEye: A Practical Solution for Real-world Logistics Routing Problems

- Implementation Roadmap: From Pilot to Full Deployment

- Metrics to Watch in Logistics Route Planning: What Tells You it’s Working

- Let Predictability Power Your Growth

When a regional logistics team suddenly has double the volume overnight, delays ripple across zones, on-time metrics collapse and dispatchers scramble to plug holes. In such a moment, predictability isn’t a luxury; it becomes survival. The U.S. logistics market is expected to hit $455 billion in revenue, growing steadily toward $671 billion by 2030.

With labor constraints tightening, the industry faces a projected shortfall of over 2 million workers this year; every misstep costs real dollars and reputation. For dispatchers and fleet operations teams, the missing piece in scaling isn’t another truck; it’s a robust logistics route planning framework that turns chaos into calibrated order.

What is Logistics Route Planning?

Before diving deeper, let’s nail down the foundation. Logistics route planning is the process of designing delivery or pickup paths across multiple stops while satisfying constraints (time windows, capacity, driver hours, vehicle type). It’s more than drawing lines on a map; it sits at the intersection of operations, data and predictive intelligence. Good routing turns raw orders into executable routes that minimize cost, delay and deviation.

In contrast, routing in logistics often emphasizes the dynamic side of how you adjust paths mid-journey in response to real-world changes (traffic, cancellations, breakdowns). Together, logistics route planning + routing in logistics form the backbone of scalable, predictable operations.

For dispatchers, that means you move from firefighting ad hoc assignments toward rule-based, optimized and auditable decision-making and your margin for error shrinks dramatically.

The Dispatcher’s Pain: Why Scale Breaks Predictability in Logistics Routing

Scaling logistics isn’t simply more volume; it amplifies complexity. Let me walk you through the core challenges you, as a dispatcher or allocator, will face and why many enterprise efforts stall.

Combinatorial Explosion and Constraint Saturation

Every new stop, time window, vehicle variant or regulation multiplies your routing possibilities exponentially. What works in one corridor fails when extended across multiple cities.

Data Noise and Model Drift

Maps change. Traffic patterns shift. Telemetry data has gaps. Predictive cost models degrade over time. Without route systems that adapt continuously, dispatch logic becomes brittle.

Real-time Disruptions

A crash, a missed stop or a last-minute order can throw off your entire day. If your routing system is fixed, you’ll be reactive and that’s costly.

Mixed Fleets, EVs and Charging Complexity

When you mix electric, ICE, refrigerated or high-capacity vehicles, each with different constraints and charging or refueling needs, routing becomes multidimensional.

Compliance and Local Regulations

Driver hours, restricted urban zones, weight limits and permits vary by jurisdiction. Manual checks become a nightmare at scale.

Cognitive Load and Decision Bottlenecks

Dispatchers can’t manually optimize 200 vehicles with constraints. Even heuristics struggle. You need automation that understands dispatch complexity.

The result? Unpredictable ETAs, inefficient utilization, rising overtime and brittle operations.

Logistics Route Planning Software as Your Predictability Engine

Now to the heart of the matter: when done right, logistics route planning becomes the lockstep mechanism that turns scaling into stability. Here’s how:

Structural Stability in Every Route

Well-constructed base routes embed slack, buffers and resilience into everyday plans. Small disruptions get absorbed without the entire route collapse.

Demand–resource Orchestration

Routing planning software optimizes which vehicle takes which stops, balancing workload, minimizing deadhead miles and matching capacity to demand.

Predictive ETA and Execution Confidence

With strong routing + predictive models, your ETAs become realistic. You align customer expectations and reduce failed deliveries or “where is my driver” calls.

Automated Decisions, Reduced Human Error

Repeatable routing logic frees dispatchers from tedious micro decisions, letting them focus on exceptions rather than pathfinding.

Scalable Replicability

Once you’ve tuned routing logic in one region, the same principles scale to new geographies or lines of business. You don’t rebuild from scratch every time.

In short, the stronger your routing engine, the narrower your variability band and variability is the enemy of predictability.

Architecture and Algorithms: How to Build Logistics Routing at Scale

Let’s go beneath the hood. If you're managing a large or growing fleet, these architectural and algorithmic principles matter deeply.

Core Architectural Pillars

- Data Inputs and Integration: Real-time traffic, telemetry order systems, geospatial layers, regulation/zone data

- Predictive Engines: Travel time estimators, energy/battery consumption models, delay models

- Optimizer Core: Global planner for assignment, local planner for routing inside zones

- Execution Layer: Mobile driver app, dynamic push updates, exception captures

- Feedback Loop: Log deviations, measure plan vs actual, refine model parameters

- Constraints and Governance Module: Enforce hours, permits, zone bans; record overrides

- Scalability Infrastructure: Partitioning, caching, parallel compute, heuristics

Together, these layers let you scale without degrading responsiveness or control.

Key Algorithmic Strategies for Scale

- Geographic Decomposition and Zoning: Split your service area into logical zones so each routing instance is tractable

- Incremental/Local Reoptimization: Don’t re-resolve the entire fleet when one vehicle gets delayed; tweak locally

- Hybrid Heuristics + ML Guidance: Use heuristics as a backbone, enhanced or guided by learned predictions

- Sparsification and Pruning: Drop dominated arcs, keep candidate sets small

- Co-optimization (EV + Routing): Insert charging stops, manage state-of-charge transitions, exploit non-dominated arcs

- Robust/Stochastic Planning: Use buffers or worst-case scenario hedging

- Parallel and Distributed Compute: Route multiple zones concurrently

- Adaptive Parameter Tuning: Tune algorithm weights using live data

- Explainability and Versioning: Let dispatchers see why route A was chosen, keep routing versions auditable

These techniques turn what would otherwise be intractable into production-quality logistics route planning.

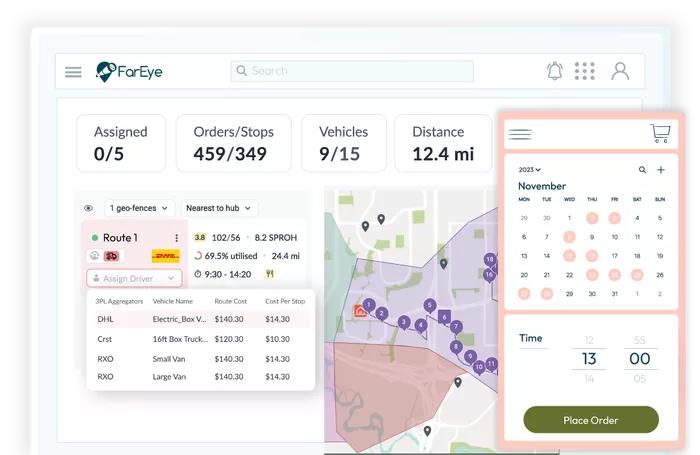

FarEye: A Practical Solution for Real-world Logistics Routing Problems

At this point, you might wonder: “Is there a system built ready to shoulder all this complexity?” That’s where FarEye steps in. Our platform is purpose-built for logistics routing and route planning at scale.

Below are capabilities that dispatchers and allocators especially care about and how FarEye addresses them.

What FarEye Brings to the Table

- Dynamic Route Optimization + Real-Time Updates

FarEye continuously adapts routes mid-execution when traffic, weather or events shift. - AI/Machine Learning–driven Routing

FarEye uses ML to estimate travel times, predict delays and guide route heuristics for better decisions under uncertainty. - Multi-stop and Constraint-rich Routing

Our system handles hundreds of constraints, time windows, vehicle types, driver hours and load capacities, making route plans feasible and robust. - Scalability and Automation

FarEye supports large fleets and volume. Dispatchers can generate optimized routes automatically for dozens or hundreds of vehicles. - Geocoding, Address Accuracy and Data Quality

Smart geocoding ensures address precision, reducing “cannot locate” errors. - Performance Visibility and Feedback

Dashboards, route vs actual comparisons, exception logs and analytics help measure drift and enable continuous improvement. - User Reviews and Trust Signals

On G2, FarEye’s route optimization software feature is highly rated across dozens of reviews.

From Dispatcher Lens: What this Means for You

- You’ll spend far less time drawing and redrawing plans manually

- You’ll know route plans are realistic (not theoretical)

- You can allow the system to act on real-time disruptions rather than firefighting

- You’ll see where inefficiencies or deviations accumulate (so you can tune)

In many organizations, moving from manual routing or spreadsheet-based dispatch to FarEye’s AI-driven system is the pivot that unlocks predictable scale.

Implementation Roadmap: From Pilot to Full Deployment

You don’t flip a switch and get perfect scheduling. Here’s a phased path you can follow:

Pilot Phase (Single Region/Zone)

- Choose one operating zone

- Start with core constraints (time windows, capacity)

- Run side-by-side with the existing dispatch to validate

Refinement Phase

- Introduce more constraints (driver hours, mixed fleet, restricted zones)

- Incorporate exception handling and local reoptimization

- Start logging deviations, model drift detection

Regional Expansion

- Partition by geography or cluster

- Introduce orchestration across zones (rebalancing between regions)

- Scale compute and routing infrastructure

Full-Scale Optimization

- Add EV/co-route charging

- Explore stochastic/robust planning

- Automate parameter tuning and continuous learning

Innovation and Future Features

- Reinforcement learning/self-tuning routing models

- Real-time micro-adjustments

- Integration with upstream planning (inventory, demand forecasting)

Throughout, monitor KPIs, track override frequency and keep dispatchers involved so they trust the system, not fight it.

Metrics to Watch in Logistics Route Planning: What Tells You it’s Working

These metrics help you know whether your logistics routing scale is succeeding or degrading:

- On-Time Delivery (% within SLA)

- Route Deviation/Exception Rate

- Kilometers per Stop or per Order

- Fuel/Energy per Mile/Order

- Driver Overtime/Idle Time

- Frequency of Manual Overrides

- Planning/Computation Latency

- Prediction Error (Planned ETA vs Actual)

- Model Drift (worsening prediction over time)

- ROI (cost savings vs baseline)

Set thresholds and alerts, e.g., if the override rate jumps above 5%, you investigate.

Let Predictability Power Your Growth

Scaling complex logistics operations demands more than more trucks or manpower; it demands structure, precision and predictability. Logistics route planning, when architected and deployed intelligently, becomes the backbone that holds scaling together. For dispatchers and allocators, it means trading chaos for consistency, ad hoc fixes for rule-driven clarity and manual firefighting for systematic control.

FarEye, with its AI-augmented optimization, real-time re-routing, rich constraints support and scalability, provides a real-world route planning system that matches enterprise complexity. As operations grow, you won’t be chasing delays; you’ll be commanding a predictable, responsive logistics machine.

Source:

Raunaq Singh leads Product Marketing at FarEye and is a subject matter expert in last-mile delivery and logistics technology. With a deep focus on AI-led innovation, he works at the intersection of product strategy, market intelligence, and storytelling to shape how enterprises think about delivery orchestration and customer experience. His writing reflects a strong understanding of both emerging technologies and real-world operational challenges.

Let's Talk to Our Experts and Optimize Your Deliveries Today!

An expert from our team will reach out within 24 hours